Fabricant de peintures de

marquage en aérosol et leader

européen sur son secteur

Technima formule, fabrique et conditionne des peintures de marquage,

peintures de retouche et produits techniques en aérosol avec pour objectif principal,

l'innovation constante, la performance au juste coût, et le respect de l'homme et de l'environnement.

Technima développe les solutions les plus adaptées

à votre métier

Marquage lors d'opérations forestières, mobilisation et transformation des bois...

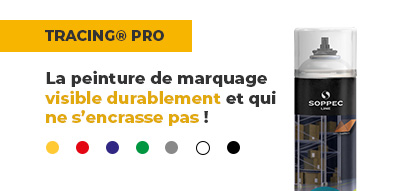

Marquage de lignes au sol et signalisation de sécurité pour structurer, délimiter et optimiser l'espace...

Marquage et balisage temporaire, délimitation d’emplacements et signalisation de zones lors d'événements...

Restauration des supports, pièces, équipement et engins utilitaires...

Nettoyage, protection et lubrification d'engins, pièces, engrenages et machines.

Nous développons nos produits dans le but de répondre aux besoins les plus spécifiques

de nos utilisateurs.

Nos gammes de produits sont ainsi déclinées selon les univers d'utilisation concernés...

Nos sélections de Produits

Notre blog

Découvrez les derniers articles et tous les meilleurs conseils Technima sur notre blog.

Ces contenus sont là pour vous, alors faites-vous plaisir !

Nos actualités

-

Divers

L'alliance bienveillante entre Technima et l'Office National des Forêts (ONF)

Nous sommes ravis de pouvoir vous parler de notre partenariat mêlant industrie et nature.

06 nov. 2023 En savoir plus -

Divers

Pochoir industriel : Conseils sur la Signalétique à utiliser en Entrepôt

Vous cherchez à réaliser une signalétique dans un entrepôt industriel ? Retrouvez nos conseils d’application avec l’utilisation de pochoirs industriels.

29 juil. 2022 En savoir plus -

Divers

Réaliser un traçage de ligne sur un terrain de foot

Retrouvez dans ce guide tous nos conseils et matériel nécessaire à la réalisation d’un traçage de lignes sur terrain de foot !

28 juil. 2022 En savoir plus

Fabricant de produits SOPPEC depuis 1962

Technima s'illustre via sa marque forte SOPPEC, première pierre à l'édifice qu'est devenu le groupe.

L'expertise accumulée depuis plus de 60 ans fait aujourd'hui de Technima un fabricant de peinture de marquage en aérosol leader sur son secteur.

Le groupe valorise également son savoir-faire dans le monde des peintures de retouche et produits techniques en aérosol.

Découvrez les gammes de produits SOPPEC, et trouvez la solution qui vous conviendra le plus.

Pourquoi choisir Technima ?

En tant que fabricant de produits en aérosol SOPPEC et expert dans son domaine, Technima s'attache à développer, en accord avec les besoins de ses clients, les solutions les plus innovantes et les plus sécurisées du marché.

Technima attache une importance particulière à anticiper et être en conformité avec les réglementations en vigueur.

Innovation

Par l'écoute attentive de ses clients, Technima conduit sa politique de développement produit et garantit à ses utilisateurs les solutions les plus innovantes et performantes du marché.

Sécurité

Technima a été le premier fabricant au monde à équiper ses peintures de marquage avec des capots de sécurité brevetés. Nous formulons et conditionnons nos produits dans un soucis constant de protection de nos utilisateurs.

Respect des réglementations

Technima garantit la conformité réglementaire des produits dans les pays où ils sont commercialisés.

Responsabilité Sociétale des Entreprises

Technima est engagé dans une démarche RSE basée sur le bilan carbone, l'analyse du cycle de vie de ses produits et la réduction de leur impact jusqu'au stade de déchet.

Un fabricant aux multiples certifications

Triple certification ISO

Depuis 2004, Technima France est certifié :

- ISO 9001 pour la Qualité

- ISO 14001 pour l'Environnement

- ISO 45001 pour la Santé et la Sécurité au travail

Médaille d'Or EcoVadis

Technima France obtient en 2022 la médaille d'or EcoVadis.